HMC 5-200

Stability, innovation and crimping power characterize the UNIFLEX HMC crimping machine.

Not only is this press capable of crimping the largest hoses ever for a UNIFLEX press, it is also the most compact for mobile use in UNIFLEX history. The HMC 12-2000 is the most solid C-crimper in the 2000 ton category with integrated powerbooster for high crimping forces. After a long period of research and development in the field of FEM, this machine surpasses all others in its category. The new HMC 5-200 completes the range of open crimping machines with 200 tons and 4″ capacity. UNIFLEX defines new crimping techniques and focuses on the highest quality and user-friendliness as well as advanced materials.

Features

High-level components and system solutions

- HiLo cylinder – higher performance with reduced heat generation/ without overheating

- Compact design allows ergonomic working and mobile use for stationary workpieces

- Radial feeding possibility of the workpieces

- Crimping of all valve types due to long base jaws

Patented construction

- Latest FEM calculation findings applied

- Tool unit completely removable

- Stable, innovative Easy to maintain

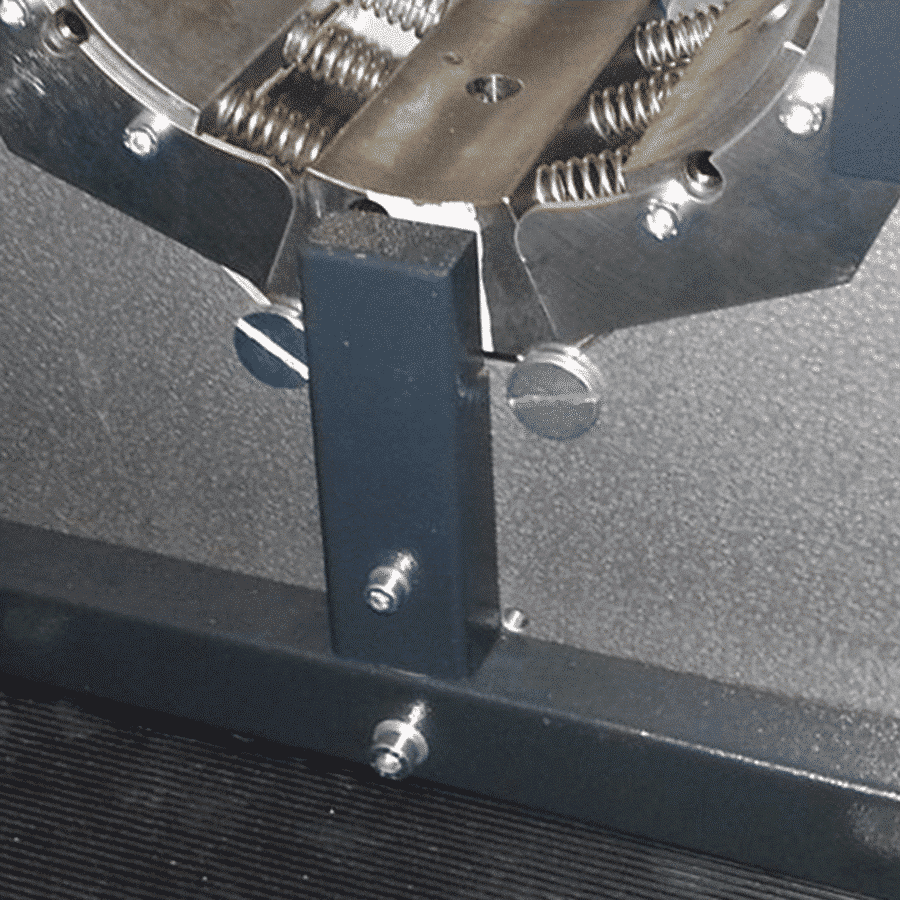

Plain bearing technology

- Lubricant-free – for more cleanliness and a longer service life of the machine

- Maximum productivity, with extremely low operating costs

- Reduces press force loss by up to 20%

- High process and repeat accuracy

CE compliant

Technical data

-

-

HMC 5-200

-

Crimp force (kN/Ton)

-

2000 / 200

-

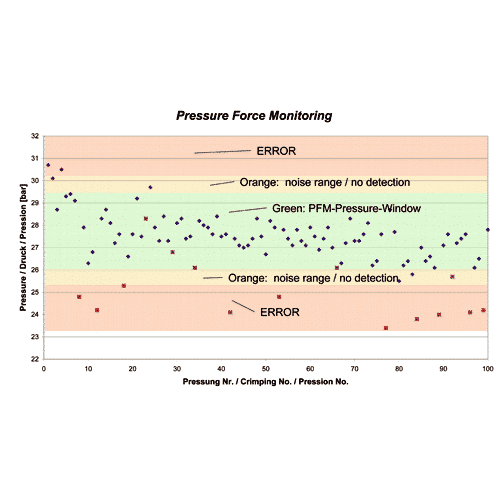

Lubrication eliminated: 20% less friction

-

-

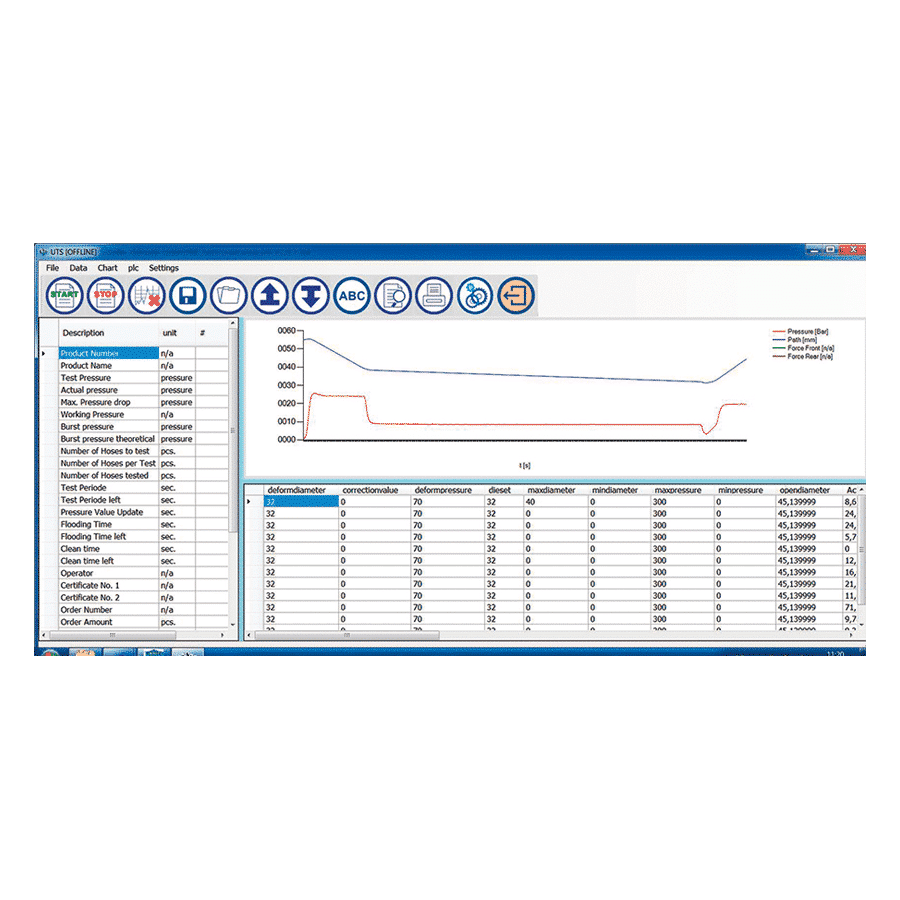

Control

-

Control C.2 + Touch

-

SAE R 15 / 4SH* 1 piece fitting

-

2″

-

SAE R 15 / 4SH* 2 piece fitting

-

11/2″

-

Max. crimp range (mm)

-

185

-

Opening without dies (mm)

-

155

-

Type of dies

-

237,239

-

Industrial

-

4″

-

90° Elbows

-

4″

-

Closing speed (mm/sec)

-

Auf Anfrage, abhängig vom Aggregat

-

Pressing speed (mm/sec)

-

Auf Anfrage, abhängig vom Aggregat

-

Opening speed (mm/sec)

-

Auf Anfrage, abhängig vom Aggregat

-

Oil (l)

-

100

-

Length machine (mm)

-

1100

-

Width machine (mm)

-

810

-

Height machine (mm)

-

1750

-

Weight (kg)

-

1650

-

Options

Video

First Class Advantages

Standard

The following products are supplied with the purchase of the product and are included in the price.

Control C.2 Accessories

Description

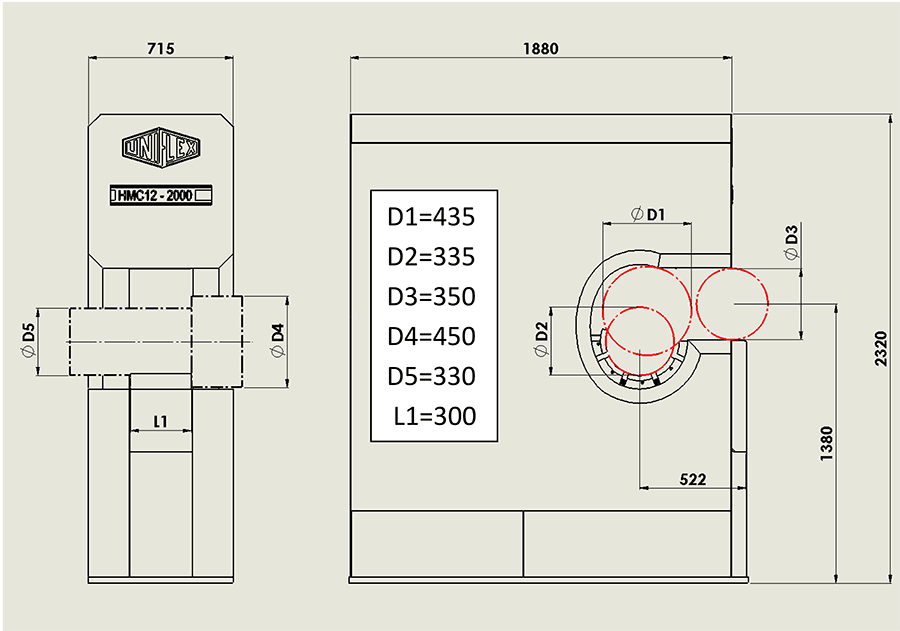

D3 = Max. radial feed opening 350 mm

D4 = Max. Flange diameter 450 mm

D5 = Nominal diameter base jaws (gauge) 330 mm

L1 = Width base jaws 300 mm

Catalogues

20.56 MB | 2. February 2024

12.52 MB | 14. March 2024

11.5 MB | 14. March 2024

12.87 MB | 7. June 2022

1.24 MB | 11. November 2022

4.06 MB | 14. March 2024

3.44 MB | 11. November 2022

1.62 MB | 11. November 2022

868.80 KB | 11. November 2022

2.79 MB | 31. July 2023