… sometimes shows itself only in a detail.

At UNIFLEX, there are several at once. (see below)

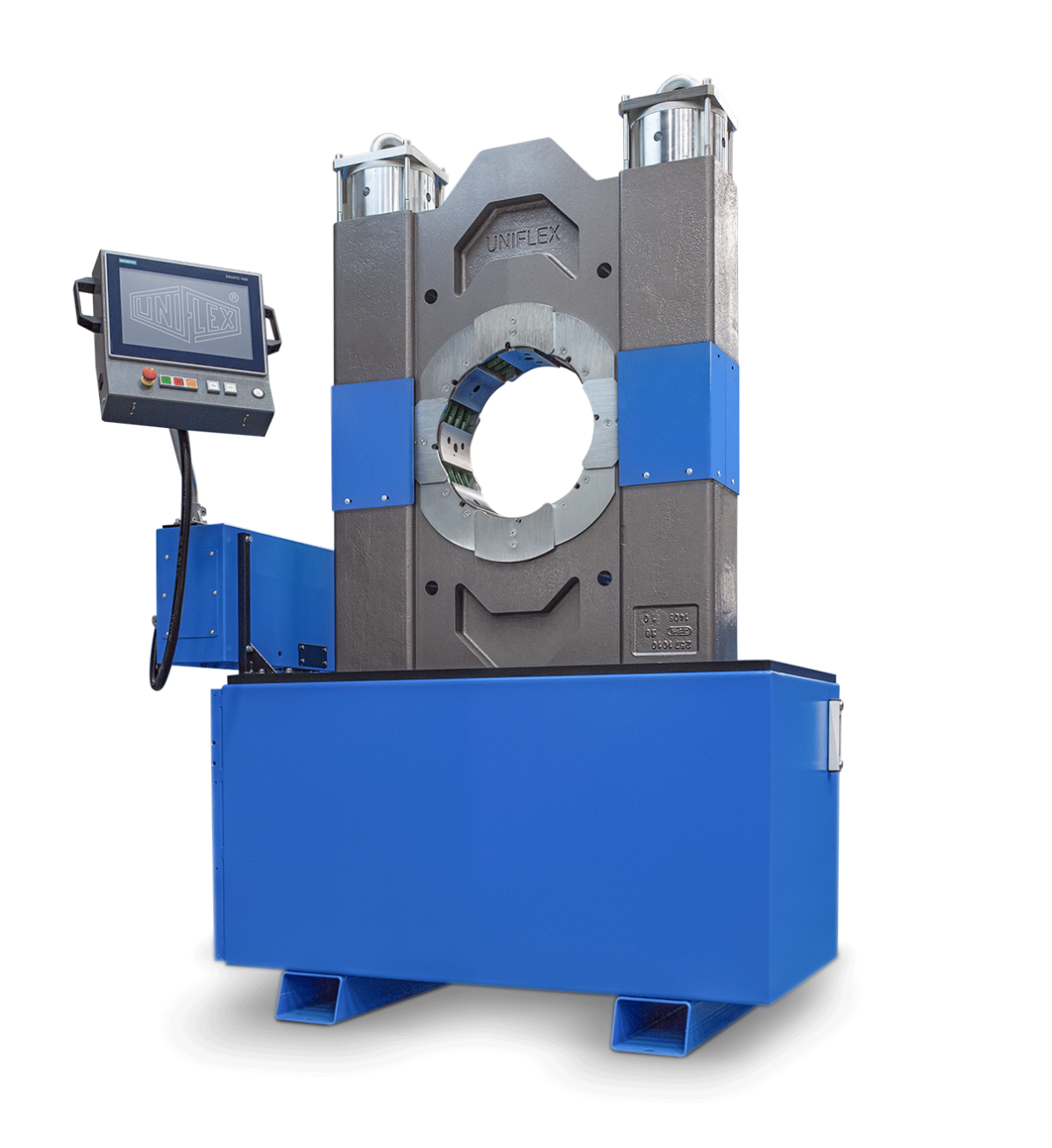

With state-of-the-art, robust and extremely durable technology, UNIFLEX stands for meeting the highest requirements – worldwide. Combined with recognized user-friendliness and exceptional customer-oriented service, UNIFLEX guarantees its customers – and their customers – a secure return on investment.

Sustainability

CO2 – Reduction

To protect our environment, UNIFLEX

relies on durable and weight-reduced equipment.

CO2 Savings

Energy consumption

Lifetime

UNIFLEX Drahtloses Management System

UWMS

The whole world is talking about digital transformation, UNIFLEX is acting – has been acting for a long time in order to be able to offer its demanding customers innovative, computer-controlled equipment.

UNIFLEX Paperless Management System

UPMS

UNIFLEX has developed a complete, paperless management system that allows you to pull data directly from your ERP system and put it on a dashboard. This way, you control all your machines purely virtually via work orders and the chronological individual retrieval of production data.

Targeted production control and optimization of production processes

Reduced lead times

Error minimization due to elimination of manual entries

Traceability of production data

Statistical evaluation of production data

Digital & innovative

The machine manufactory

At UNIFLEX there are no assembly lines and no large-scale production. The hose presses and all other devices and machines are manufactured in the classic manufactory process, by hand and for the most part only on order. Each press is therefore a carefully assembled individual item “Made in Germany” by well-trained specialists. Special designs and customized variants are therefore also feasible at any time.

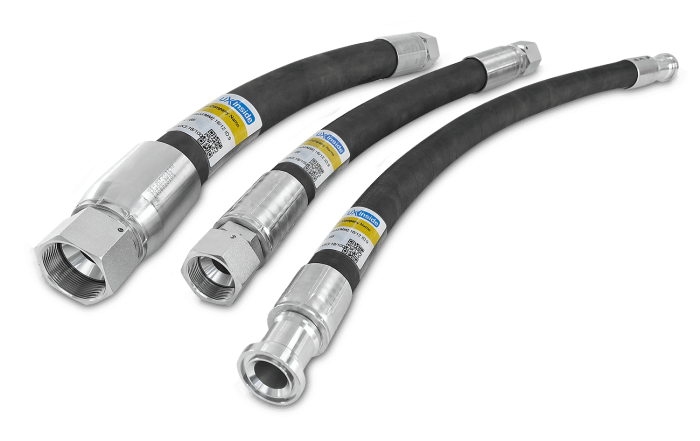

Sell quality

UX-Inside

Our training concept gives you a competitive edge

Further training is an important investment in the future of a company in order to maintain or increase quality and safety.

We offer our customers training that enables them to manufacture safe hose assemblies that meet the high requirements.

Get certified!

Sign up for training.

First-class trained personnel with a high level of expertise bring the decisive competitive advantages. Manufacturing hose assemblies on the best machines available on the world market for manufacturing hose assemblies guarantees quality.

UNIFLEX Machine

Certification

Training

ULS (UX-Inside Label)

Certified workshop

Innovation and state-of-the-art quality

Plain bearing technology

Building on the innovative edge gained through the development of slide bearing technology 50 years ago, UNIFLEX is still constantly working on the practical further and new development of sustainable and ergonomic machines for hose production and repair.