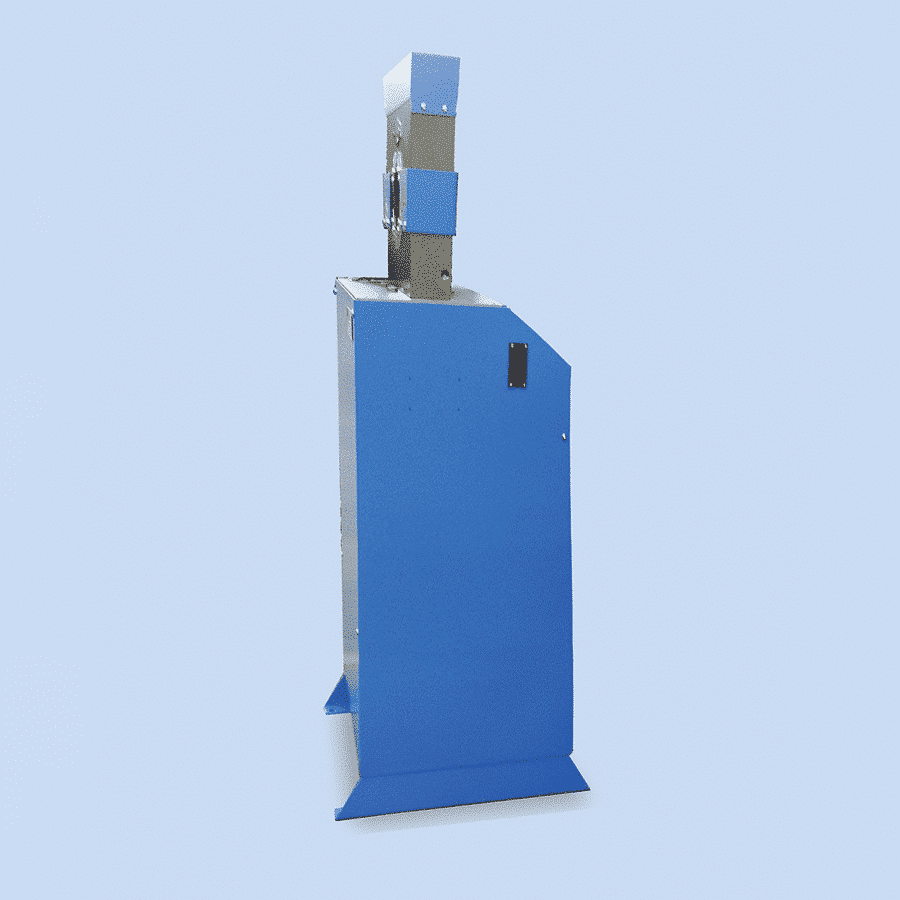

HM 220

With its slim and innovative design, high user-friendliness and long service life, the HM 220 tube press sets standards for quality and economy.

Their high pressing force and all-round good accessibility (operation from both sides as well as loading possible) offer the ideal solution for crimping nominal diameters up to 1 1/4 inch, they offer everything that a Production press needed. The proven lubrication-free slide bearing technology reduces maintenance costs. The strong Pressing forces of up to 1,600 kN complete the picture.

Features

High-level components and system solutions

- Compact design allows ergonomic working.

- HiLo cylinder – higher performance with reduced heat generation/ without overheating

- Low noise level due to high quality pumps

Fixed 6 o’clock jaw

- Safe and force-saving positioning of the workpiece

- Increases productivity and profitability

- Improves occupational safety and reduces operator fatigue

Plain bearing technology

- Lubricant-free – for more cleanliness and longer machine life

- Maximum productivity, with extremely low operating costs

- No contamination of the hose line with grease

- Ideal also for the food and pharmaceutical industry

- Reduces press force loss by up to 20%

- Consistenly accurate crimp force

CE compliant

Technical data

-

-

HM 220

-

Crimp force (kN/Ton)

-

1350 / 135

-

Lubrication eliminated: 20% less friction

-

-

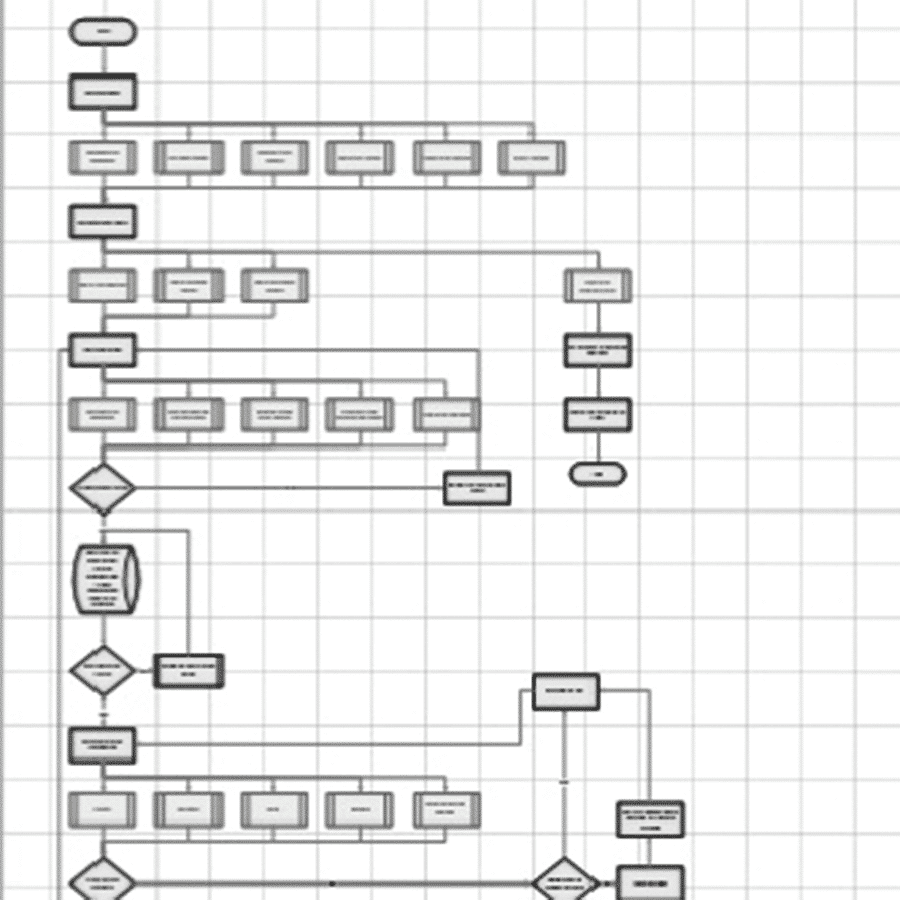

Control

-

Control C.2 + Touch

-

SAE R 15 / 4SH* 1 piece fitting

-

1¼ “

-

4SH* 2 piece fitting

-

1 “

-

SAE R 15* 2 piece fitting

-

1 “

-

Max. crimp range (mm)

-

70

-

Opening travel (mm)

-

+ 35

-

Opening without dies (mm)

-

105

-

Base jaw length (mm)

-

75

-

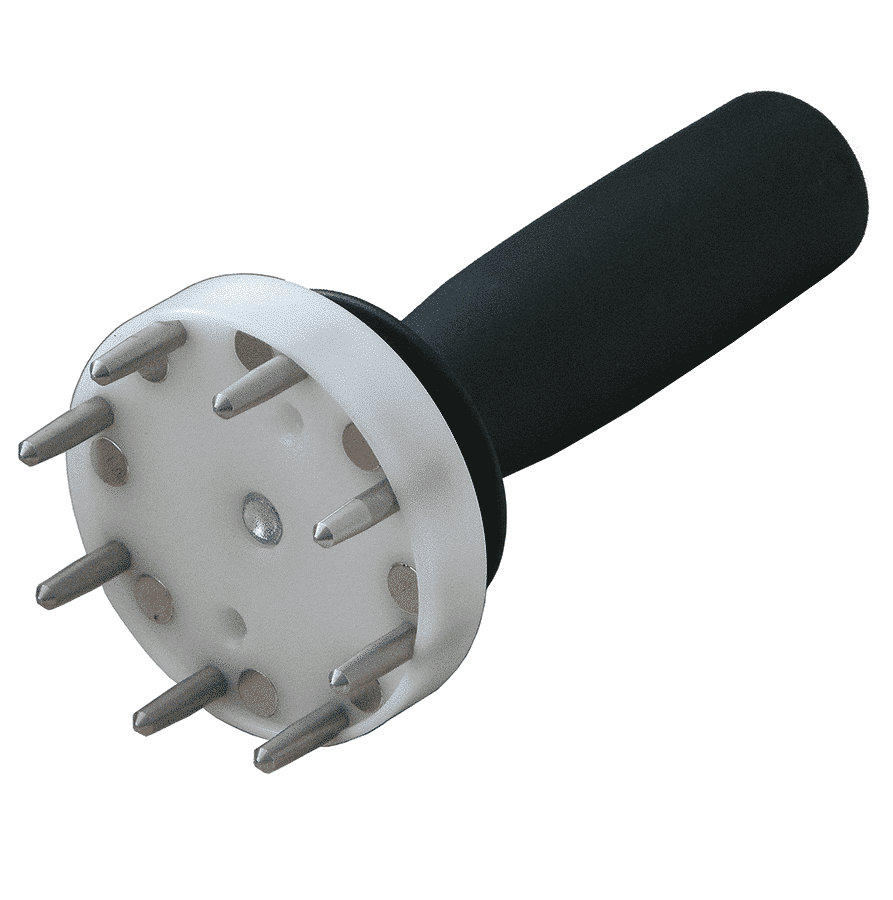

Type of dies

-

239

-

Industrial

-

2 “

-

90° Elbows

-

1½ “

-

Closing speed (mm/sec)

-

10/20

-

Pressing speed (mm/sec)

-

5/10

-

Opening speed (mm/sec)

-

10/20

-

Noise level (dBA)

-

53

-

Drive (kW)

-

5,5 kW 3 VAC

-

Oil (l)

-

80

-

Length machine (mm)

-

645

-

Width machine (mm)

-

560

-

Height machine (mm)

-

1450

-

Weight (kg)

-

310

-

Options

* Depending on the fitting.

** Standard: Half power, double speed. (Switchable by control)

*** Outside base jaw lengths: UNIFLEX REQUEST

Video

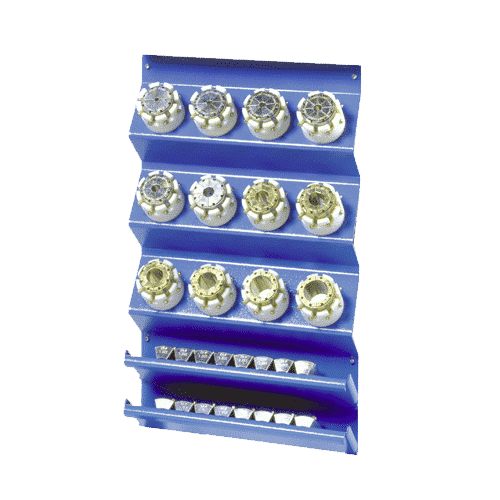

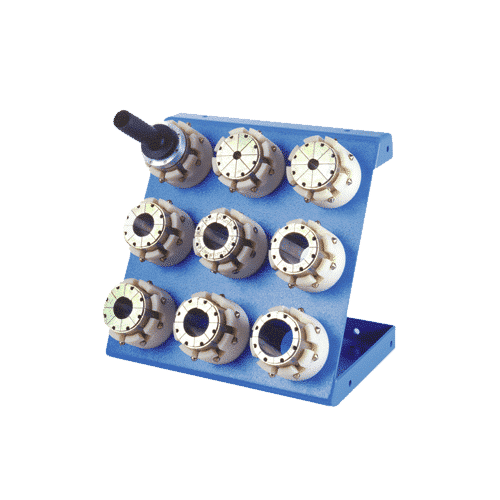

Type of dies

| ø mm | -mm- |

|---|---|

| 6,8 | 50 |

| 9 | 50 |

| 10 | 50 |

| 12 | 50 |

| 14 | 60 |

| 16 | 60 |

| 17 | 60 |

| 19 | 60 |

| 20 | 60 |

| 22 | 60 |

| 24 | 60 |

| 26 | 75 |

| 28 | 75 |

| 30 | 75 |

| 31 | 75 |

| 32 | 75 |

| 34 | 75 |

| 36 | 75 |

| 38 | 75 |

| 39 | 75 |

| 40 | 75 |

| 44 | 75 |

| 47 | 75 |

| 50 | 75 |

| 54 | 75 |

| 57 | 75 |

| 62 | 75 |

First Class Advantages

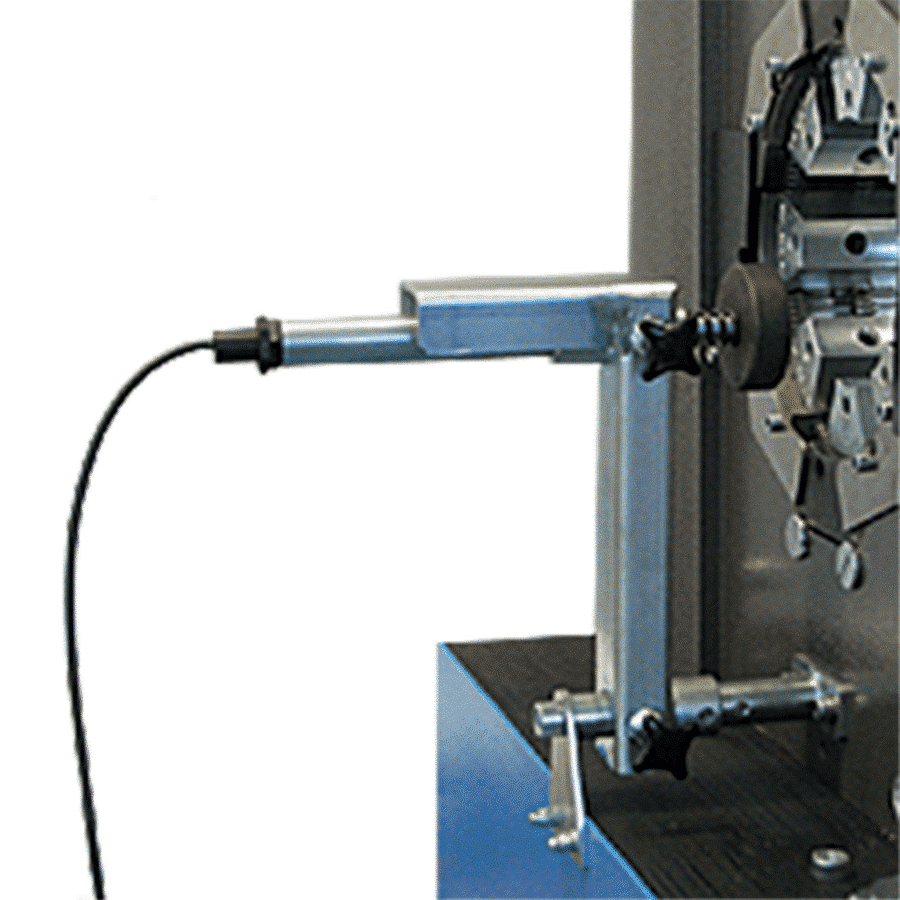

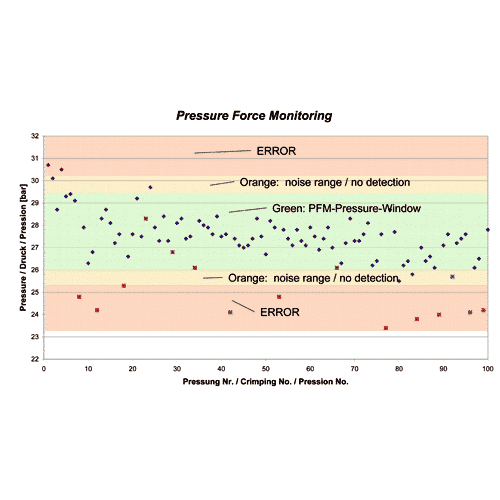

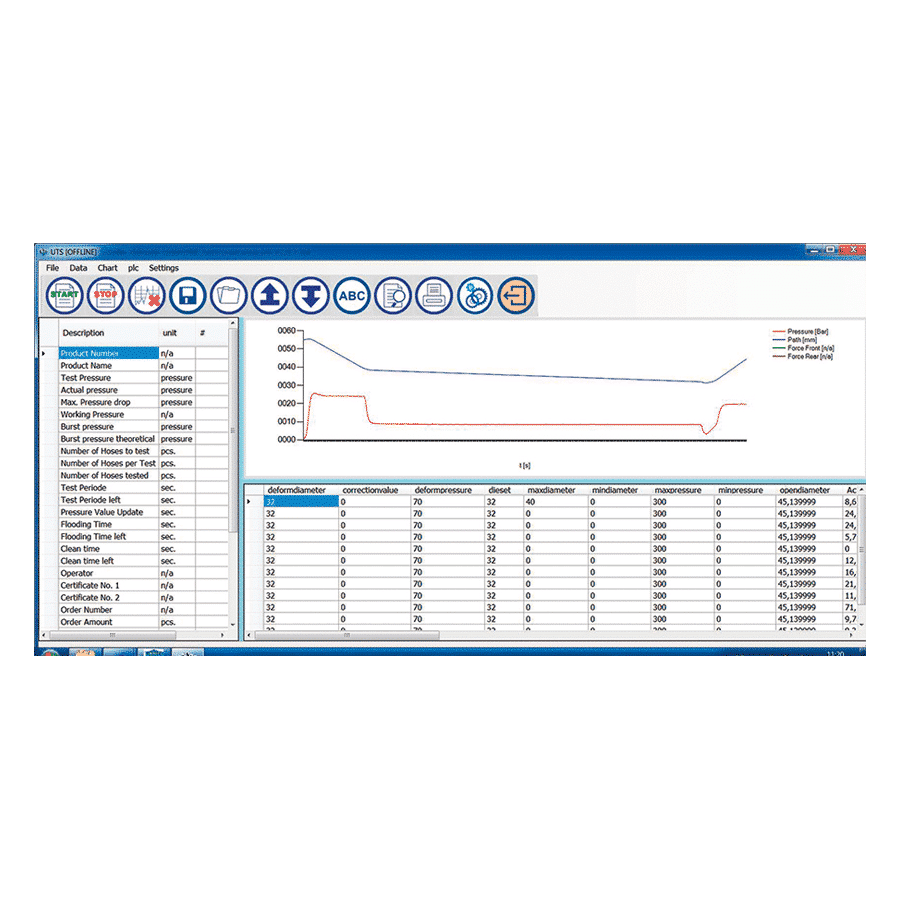

Control C.2 Accessories

Description

Catalogues

20.56 MB | 2. February 2024

12.52 MB | 14. March 2024

11.5 MB | 14. March 2024

12.87 MB | 7. June 2022

1.24 MB | 11. November 2022

4.06 MB | 14. March 2024

3.44 MB | 11. November 2022

1.62 MB | 11. November 2022

868.80 KB | 11. November 2022

2.79 MB | 31. July 2023